ABS: The Engineering Marvel Behind Modern Innovation

2025-03-12 09:08:09

How ABS Plastic Powers Durability, Design, and Sustainability

In the world of engineering plastics, ABS (Acrylonitrile Butadiene Styrene) stands out as a material that combines strength, versatility, and aesthetic appeal. From the gadgets we use daily to the vehicles we drive, ABS is the unsung hero that makes modern life possible. Let’s explore how this remarkable material is transforming industries and driving innovation.

1. The Perfect Blend of Strength and Flexibility

ABS is renowned for its unique combination of properties:

-

Impact Resistance: ABS can withstand heavy impacts without cracking, making it ideal for protective gear, helmets, and automotive parts.

-

Durability: Its robust nature ensures long-lasting performance in demanding environments.

-

Lightweight: ABS offers strength without adding significant weight, a critical factor in automotive and aerospace applications.

Did you know? ABS is 30% lighter than traditional materials like metal, while maintaining comparable strength (Plastics Engineering Journal).

2. A Designer’s Dream Material

ABS’s versatility makes it a favorite among designers and engineers:

-

Ease of Machining: ABS can be easily cut, drilled, and shaped, allowing for intricate designs and prototypes.

-

Surface Finish: Its smooth surface can be painted, polished, or textured, making it perfect for consumer products.

-

3D Printing: ABS is a popular filament choice for 3D printing due to its strength and ease of use.

3. Applications Across Industries

ABS’s adaptability makes it a go-to material for countless applications:

-

Automotive: Used in dashboards, interior trim, and wheel covers, ABS enhances both aesthetics and functionality.

-

Electronics: ABS is the material of choice for phone cases, keyboard keys, and computer housings due to its durability and insulation properties.

-

Toys: LEGO bricks are made from ABS, showcasing its safety, durability, and vibrant color options.

-

Construction: ABS pipes and fittings are corrosion-resistant and easy to install, making them ideal for plumbing systems.

4. Safety and Compliance

ABS is a trusted material in applications where safety is paramount:

-

Flame Retardancy: Special formulations of ABS meet strict fire safety standards for use in electronics and construction.

-

Non-Toxic: ABS is safe for use in food containers, medical devices, and children’s toys.

-

Chemical Resistance: It resists oils, acids, and alkalis, ensuring reliability in industrial settings.

5. Sustainability and Recyclability

ABS is not just versatile—it’s also a sustainable choice:

-

Recyclable: ABS can be melted down and reused, reducing waste and supporting circular economy initiatives.

-

Energy Efficiency: ABS production consumes less energy compared to metals, lowering its carbon footprint.

-

Longevity: Its durability means fewer replacements, reducing resource consumption over time.

Why Choose ABS?

-

Cost-Effective: ABS offers high performance at a lower cost than many alternatives.

-

Design Freedom: Its ease of molding and finishing allows for creative and functional designs.

-

Eco-Friendly: Recyclable and energy-efficient, ABS aligns with global sustainability goals.

-

Proven Performance: Decades of use across industries attest to its reliability and versatility.

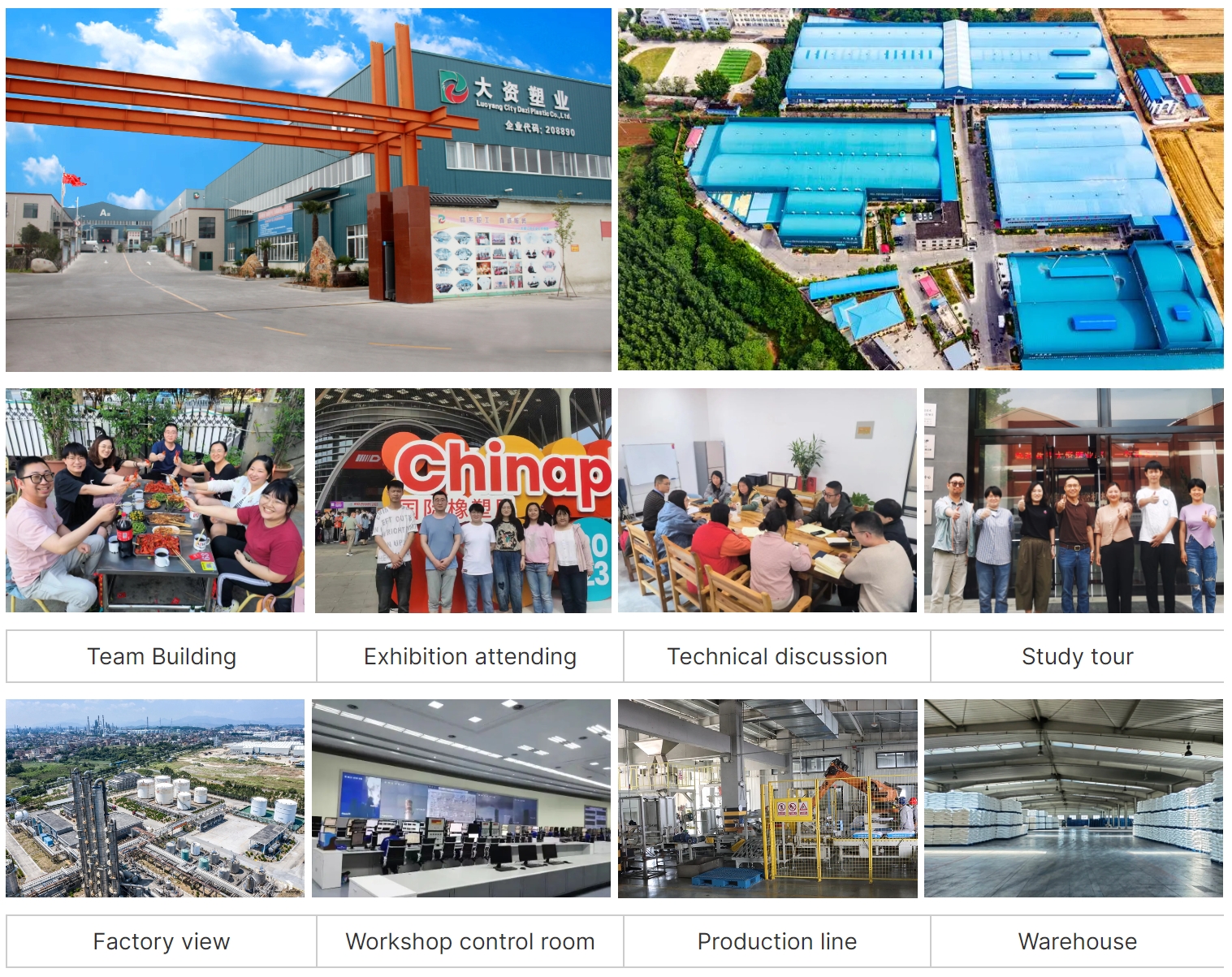

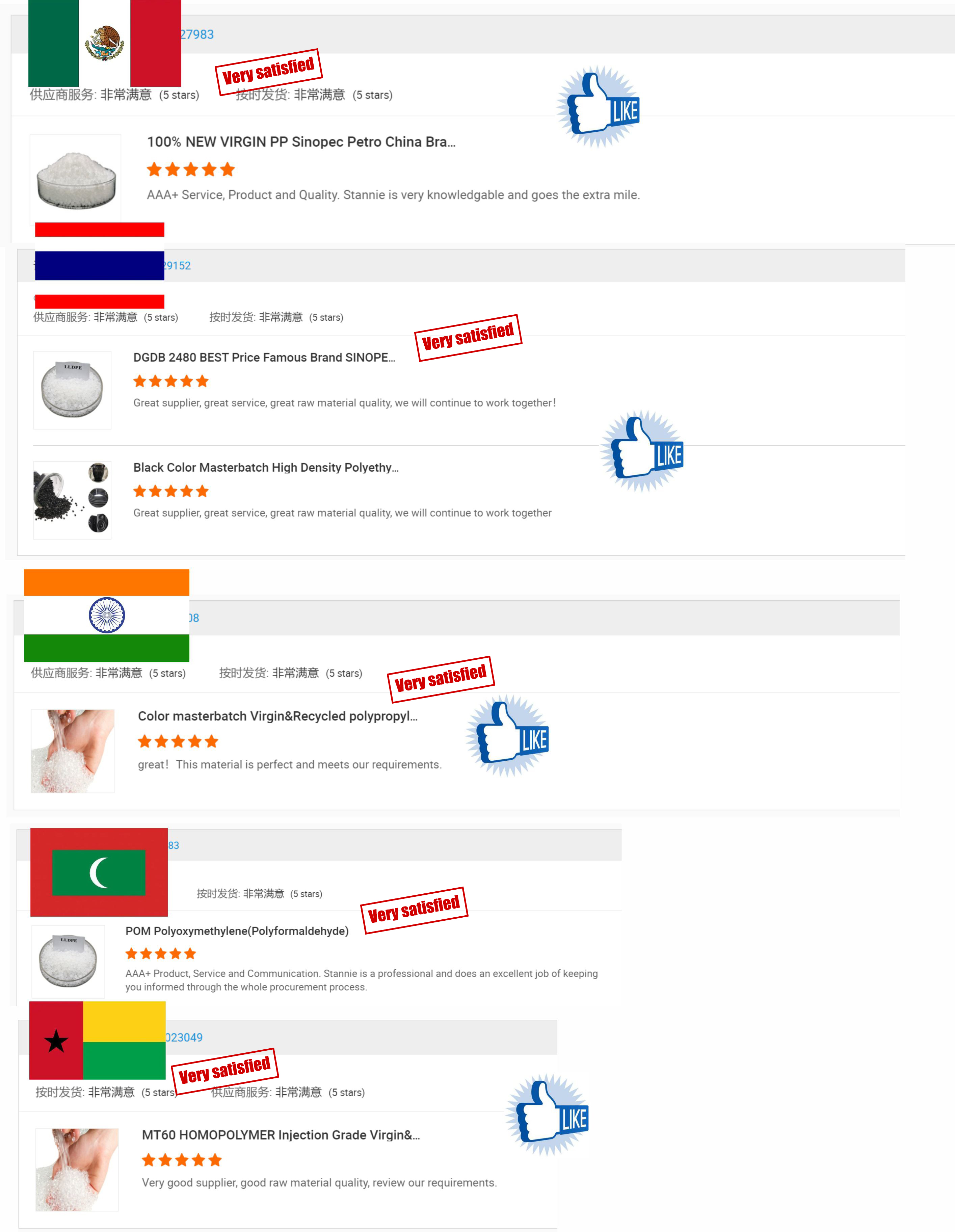

We have established long-term cooperative relations with more than 60+ well-known enterprises all over the world

Our company has 12 certifications and 57+ patents.

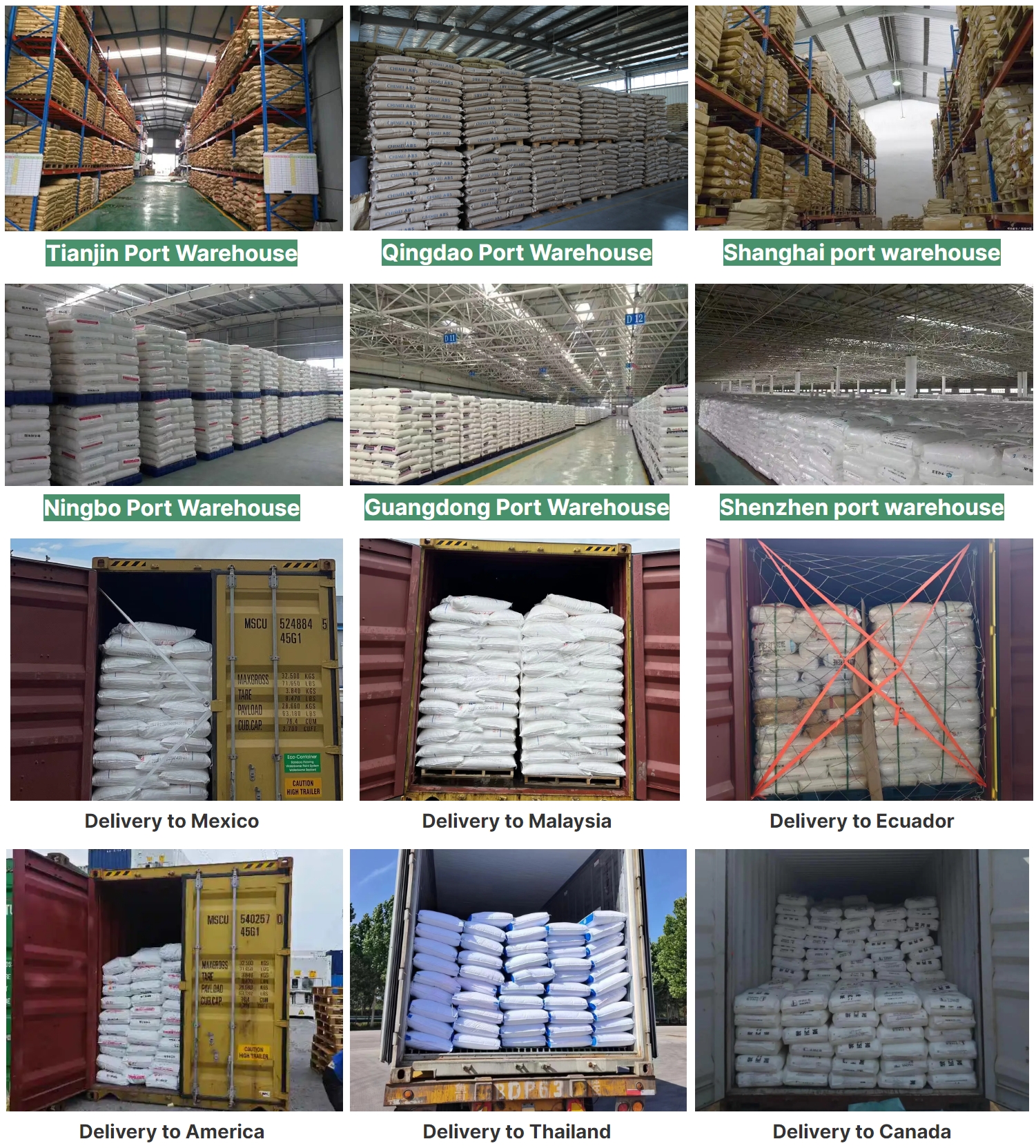

23 years' experience Professional purchasing consultant with a supply chain of 1200+ plastic raw materials in China.