Polypropylene: The Unsung Hero of Modern Manufacturing

2025-03-07 17:28:53

Polypropylene: The Unsung Hero of Modern Manufacturing

How PP Drives Innovation Across Industries with Versatility and Sustainability

In the world of polymers, polypropylene (PP) stands out as a material that combines strength, adaptability, and eco-friendliness. From everyday household items to cutting-edge industrial applications, PP is quietly revolutionizing how we live, work, and innovate. Let’s dive into the many ways polypropylene is shaping industries and delivering sustainable solutions.

1. Packaging That Protects and Preserves

Polypropylene is a game-changer in the packaging industry, offering unmatched versatility:

-

Food Safety: PP’s non-toxic, FDA-approved properties make it ideal for food containers, yogurt cups, and microwave-safe trays.

-

Durability: Lightweight yet strong, PP packaging resists cracks and impacts, ensuring products reach consumers intact.

-

Sustainability: With a recycling code of 5, PP is increasingly used in reusable containers and eco-friendly packaging solutions.

Did you know? PP packaging can reduce food waste by up to 30% due to its excellent barrier properties (World Packaging Organisation).

2. Automotive Innovation: Lighter, Stronger, Greener

The automotive industry relies on PP for its lightweight and durable properties:

-

Interior Components: Dashboard panels, door trims, and seat covers benefit from PP’s resistance to wear and tear.

-

Under-the-Hood: Battery casings, air filters, and fluid reservoirs made from PP withstand high temperatures and chemical exposure.

-

Weight Reduction: PP components help reduce vehicle weight, improving fuel efficiency and lowering carbon emissions.

Fun fact: PP accounts for nearly 30% of all plastics used in modern vehicles (Automotive Plastics Report).

3. Medical Marvels: Safe and Sterile Solutions

In healthcare, PP’s biocompatibility and sterilization resistance make it indispensable:

-

Single-Use Devices: Syringes, IV bottles, and surgical trays ensure patient safety and reduce contamination risks.

-

Protective Gear: PP is used in face masks, gowns, and medical packaging, playing a critical role in infection control.

-

Drug Delivery: PP’s stability makes it ideal for pill bottles and blister packs, ensuring medication integrity.

4. Textiles and Beyond: Comfort Meets Performance

PP fibers are transforming the textile industry:

-

Activewear: Moisture-wicking properties make PP perfect for sportswear and outdoor gear.

-

Home Furnishings: Carpets, rugs, and upholstery benefit from PP’s stain resistance and durability.

-

Industrial Applications: PP ropes, nets, and geotextiles are used in construction and agriculture for their strength and UV resistance.

5. Industrial Strength: Built to Last

PP’s chemical resistance and durability make it a top choice for industrial applications:

-

Piping Systems: PP pipes are corrosion-resistant, making them ideal for chemical transport and water systems.

-

Storage Solutions: PP tanks and containers safely store acids, solvents, and other harsh chemicals.

-

3D Printing: PP filaments are gaining popularity for prototyping and custom parts due to their flexibility and strength.

Sustainability at Its Core

Polypropylene isn’t just versatile—it’s also a sustainable choice:

-

Recyclability: PP can be recycled into new products, from automotive parts to garden furniture.

-

Energy Efficiency: PP production consumes less energy compared to other plastics, reducing its carbon footprint.

-

Circular Economy: Innovations in recycled PP (rPP) are driving the shift toward a zero-waste future.

Why Choose Polypropylene?

-

Cost-Effective: PP offers excellent performance at a lower cost than many alternatives.

-

Design Flexibility: Easily molded into complex shapes, PP enables creative and functional designs.

-

Eco-Friendly: With recyclability and energy-efficient production, PP aligns with global sustainability goals.

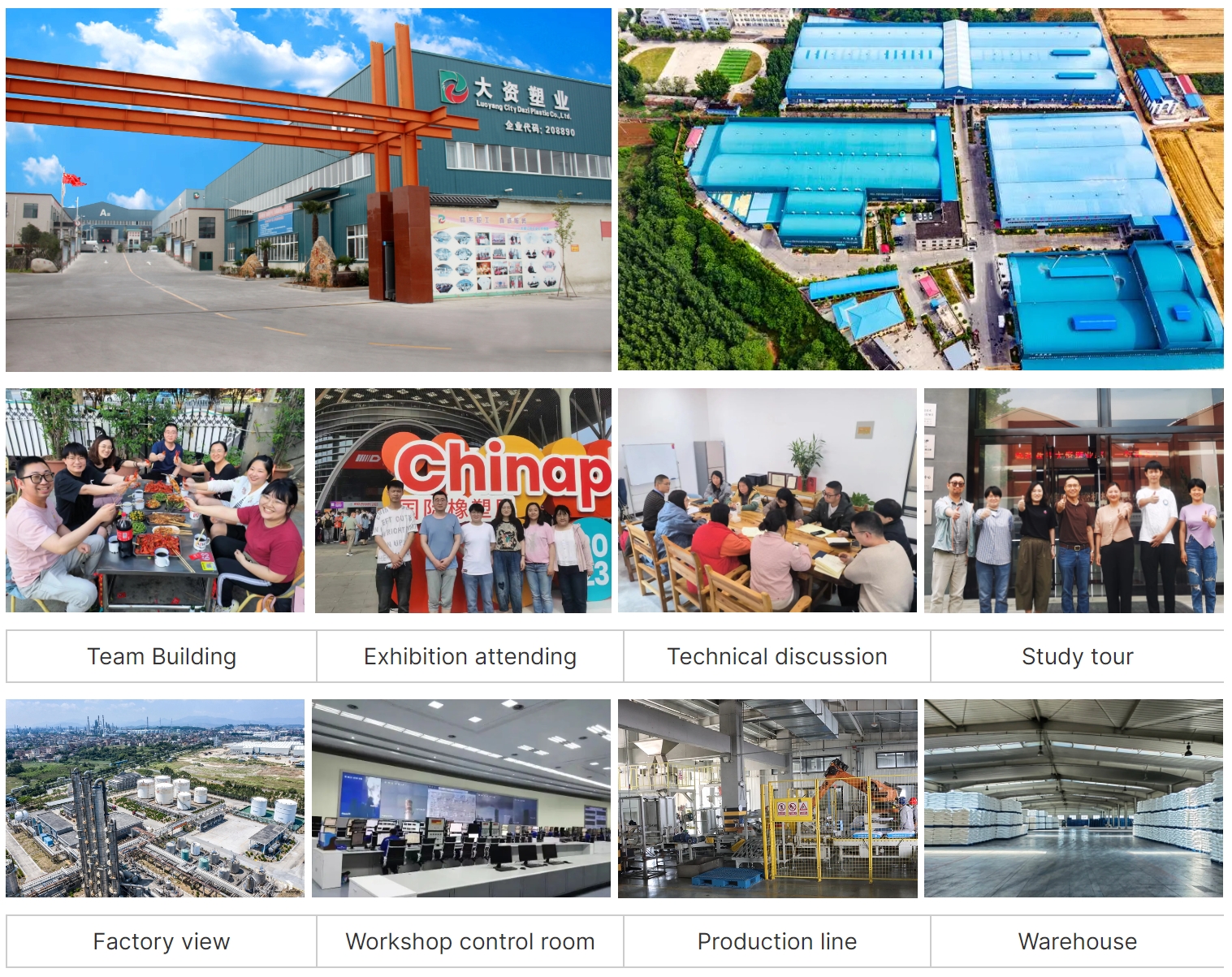

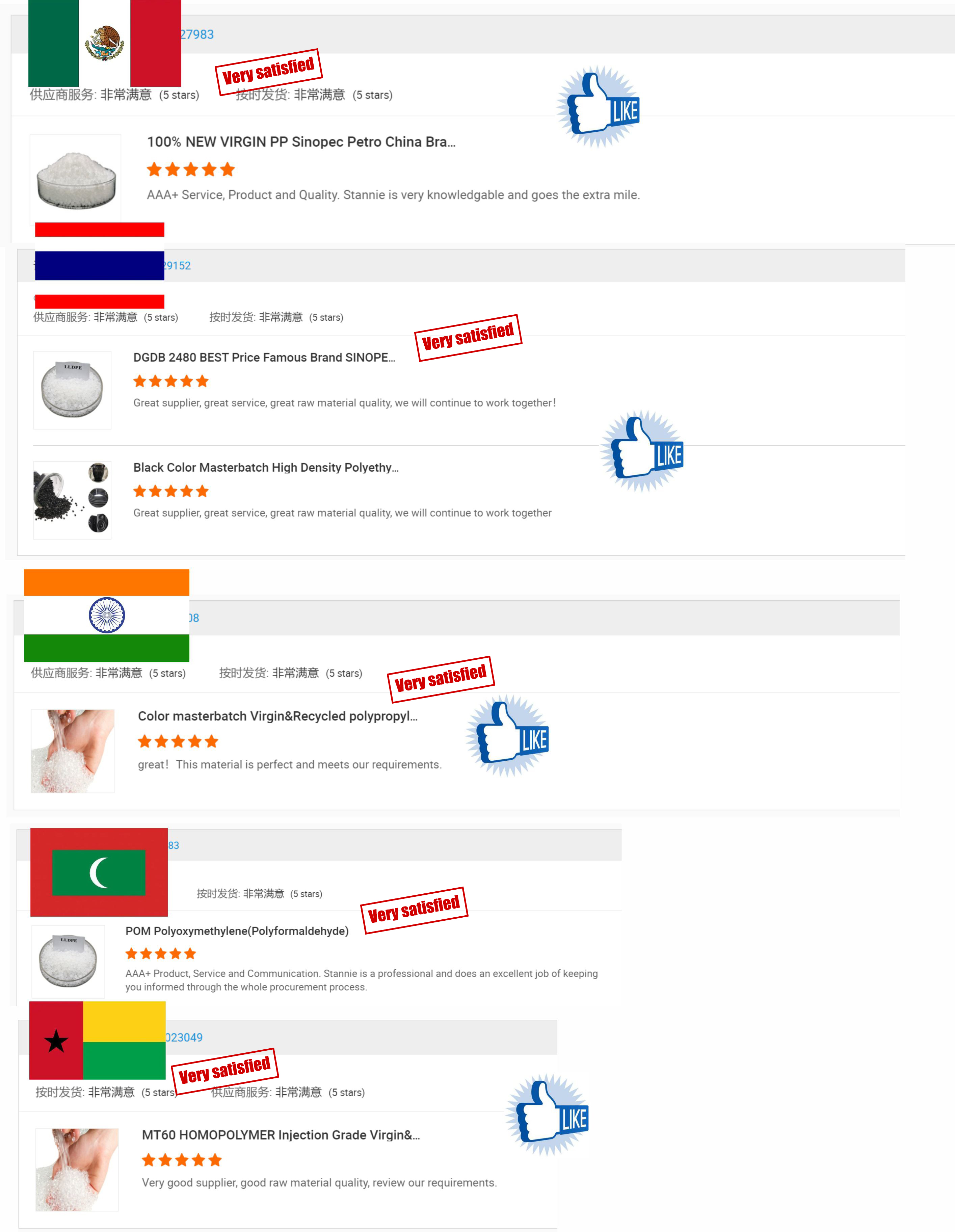

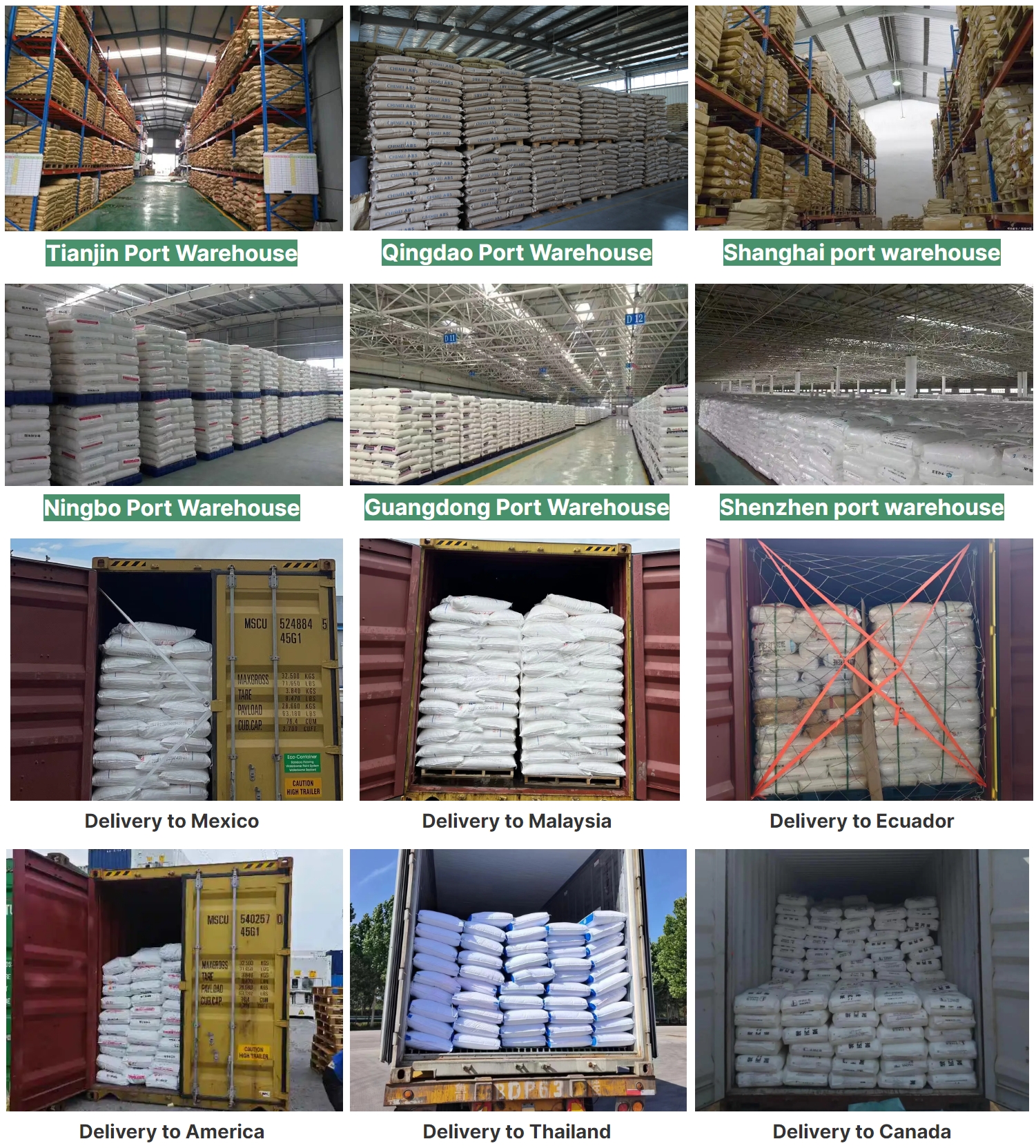

We have established long-term cooperative relations with more than 60+ well-known enterprises all over the world

Our company has 12 certifications and 57+ patents.

23 years' experience Professional purchasing consultant with a supply chain of 1200+ plastic raw materials in China.