Каким образом полипропиленовое сырье способствует устойчивому производству смолы

2023-11-01 14:52:16

Table of Contents:

1. Introduction: Understanding the Significance of Polypropylene Raw Material

2. The Versatility of Polypropylene in Resin Manufacturing

3. Polypropylene's Contribution to Sustainable Practices

4. Environmental Benefits of Polypropylene in Resin Manufacturing

5. Challenges and Limitations of Using Polypropylene

6. FAQs (Frequently Asked Questions)

7. Conclusion

## 1. Introduction: Understanding the Significance of Polypropylene Raw Material

Polypropylene, a versatile thermoplastic polymer, has gained immense popularity in various industries. Its unique properties, including durability, chemical resistance, and excellent moldability, make it an ideal choice for resin manufacturing. In this article, we will delve into the role of polypropylene raw material in producing sustainable resin and its impact on the environment.

## 2. The Versatility of Polypropylene in Resin Manufacturing

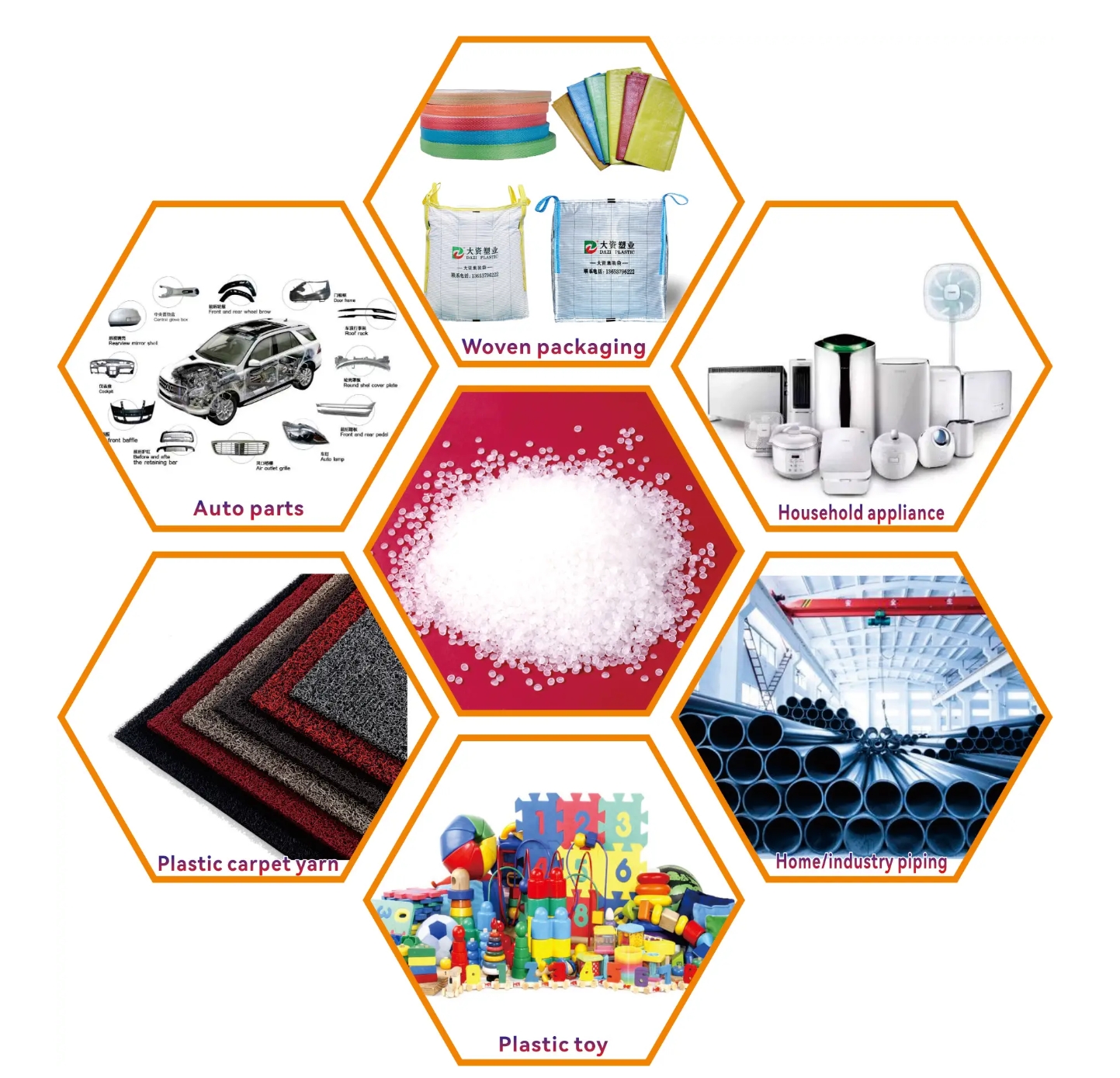

Polypropylene's versatility makes it a preferred choice for resin manufacturing. Its ability to be easily molded into different shapes and forms allows manufacturers to create a wide range of products. Polypropylene resin can be used in various applications, including packaging materials, automotive components, consumer products, and more. Its adaptability and compatibility with other materials make it an essential ingredient in resin formulations.

## 3. Polypropylene's Contribution to Sustainable Practices

The use of polypropylene raw material in resin manufacturing is a significant step towards promoting sustainable practices. Unlike other plastic materials, polypropylene is considered safe for the environment due to its low toxicity and recyclability. It can be reused and repurposed, minimizing waste and reducing the demand for new raw materials. By incorporating polypropylene into resin production, manufacturers contribute to a circular economy and reduce their ecological impact.

## 4. Environmental Benefits of Polypropylene in Resin Manufacturing

4.1 Reduced Carbon Footprint:

Using polypropylene in resin manufacturing helps reduce the carbon footprint associated with plastics. The production of polypropylene requires fewer energy resources compared to other plastics, resulting in lower greenhouse gas emissions. This eco-friendly aspect makes polypropylene an ideal choice for sustainable resin production.

4.2 Recyclability:

Polypropylene is highly recyclable, allowing for multiple life cycles. By recycling polypropylene-based resin products, manufacturers can minimize waste and conserve valuable resources. This closed-loop recycling process ensures that polypropylene remains in the production cycle, minimizing the need for virgin raw materials.

4.3 Light Weight:

Polypropylene resin is lightweight, which translates into reduced transportation costs and lower fuel consumption. The use of lightweight materials, such as polypropylene, in resin manufacturing promotes energy efficiency throughout the supply chain.

4.4 Lower Emissions:

Polypropylene resin exhibits lower emissions during the manufacturing process compared to other plastics. Its production involves fewer volatile organic compounds (VOCs) and no chlorine content. This reduces the environmental impact and improves air quality.

## 5. Challenges and Limitations of Using Polypropylene

While polypropylene offers numerous benefits, it is essential to consider its limitations and challenges in resin manufacturing. Some key points to note include:

- High melting point: Polypropylene has a relatively high melting point, which affects the processing temperature during resin manufacturing.

- Limited UV stability: Pure polypropylene resin is susceptible to UV degradation. However, additives can enhance its UV stability for specific applications.

- Lower impact resistance: Compared to other plastic materials, polypropylene may have lower impact resistance, which may limit its use in certain applications.

Despite these challenges, ongoing research and development aim to address these limitations and improve the overall performance of polypropylene in resin manufacturing.

## 6. FAQs (Frequently Asked Questions)

Q1: Can polypropylene-based resin products be recycled?

A1: Yes, polypropylene-based resin products can be recycled. The recyclability of polypropylene allows for a closed-loop recycling process, reducing waste and conserving resources.

Q2: Is polypropylene environmentally friendly?

A2: Yes, polypropylene is considered environmentally friendly due to its low toxicity, recyclability, and reduced carbon footprint compared to other plastics.

Q3: What are some common applications of polypropylene-based resin?

A3: Polypropylene-based resin finds applications in packaging materials, automotive components, consumer products, and various other industries due to its versatility and durability.

Q4: Does polypropylene help reduce greenhouse gas emissions?

A4: Yes, the production of polypropylene requires fewer energy resources, resulting in lower greenhouse gas emissions compared to other plastics.

Q5: Are there any alternatives to polypropylene for sustainable resin manufacturing?

A5: While there are alternative materials available, polypropylene remains a popular choice for sustainable resin manufacturing due to its unique properties and recyclability.

## 7. Conclusion

Polypropylene raw material plays a significant role in sustainable resin manufacturing. Its versatility, recyclability, and reduced environmental impact make it an ideal choice for manufacturers aiming to reduce their carbon footprint. By incorporating polypropylene into resin production, we can promote a circular economy and contribute to a more sustainable future. Embracing this eco-friendly material is a step towards creating a greener and cleaner planet for generations to come.

|

Category

|

Grade

|

MFI

|

Density

|

Major Applications

|

|

Homopolymer - Extrusion

|

F103

|

3.3

|

0.9

|

BOPP Film Grade - General Purpose, Lamination & Metallizable films

|

|

T30S

|

3.3

|

0.9

|

Raffia Tapes ,Woven Sacks for Packaging Fertilizers, Cement, Polymers, Carpet Backing ,FIBC etc.

|

|

|

T103

|

3.3

|

0.9

|

Thermoformed Cups, Containers & Other disposable items

|

|

|

F110

|

11

|

0.9

|

TQ and Cast Films for General Purpose Packaging etc.

|

|

|

Homopolymer – Injection Molding

|

M103

|

3

|

0.9

|

General Purpose Injection Molding

|

|

M106

|

6

|

0.9

|

General Purpose Injection Molding

|

|

|

M108

|

8

|

0.9

|

General Purpose Injection Molding

|

|

|

M110

|

10

|

0.9

|

General Purpose Injection Molding, Furniture etc.

|

|

|

Impact Copolymer – Injection Molding

|

M304

|

3.5

|

0.9

|

General Purpose Injection Molding

|

|

M310

|

10

|

0.9

|

Battery Boxes

|

|

|

M311T

|

10

|

0.9

|

Compounding, Automotive Components, Luggage and Industrial Components

|

|

|

M312

|

12

|

0.9

|

Compounding, Industrial Components, Automotive Components, Luggage, Pails, Houseware, Sanitary Wares etc.

|

|

|

M315

|

15

|

0.9

|

General Purpose Injection Molding

|

|

|

M325

|

25

|

0.9

|

Compounding, Automotive Components, Houseware, Appliances parts, Extrusion Coating

|

|

|

M340

|

40

|

0.9

|

Appliance & White Goods, Automotive component, Compounding,TWIM

|

|

|

M307

|

7

|

0.9

|

General Purpose Injection Molding

|

|

|

Random Copolymer – Blow Molding

|

B202S

|

1.9

|

0.9

|

Bottle & Containers for Medical and Transparent Products (e.g. IV Fluid Bottles) etc

|

|

B200

|

1.9

|

0.9

|

General Purpose Blow Molded & Thermoformed Items, Sheets for Files & Folders.

|

|

|

M212S

|

12

|

0.9

|

High Clarity Containers, Household items,Injection Syringe, Laboratory products & ISBM Bottles

|

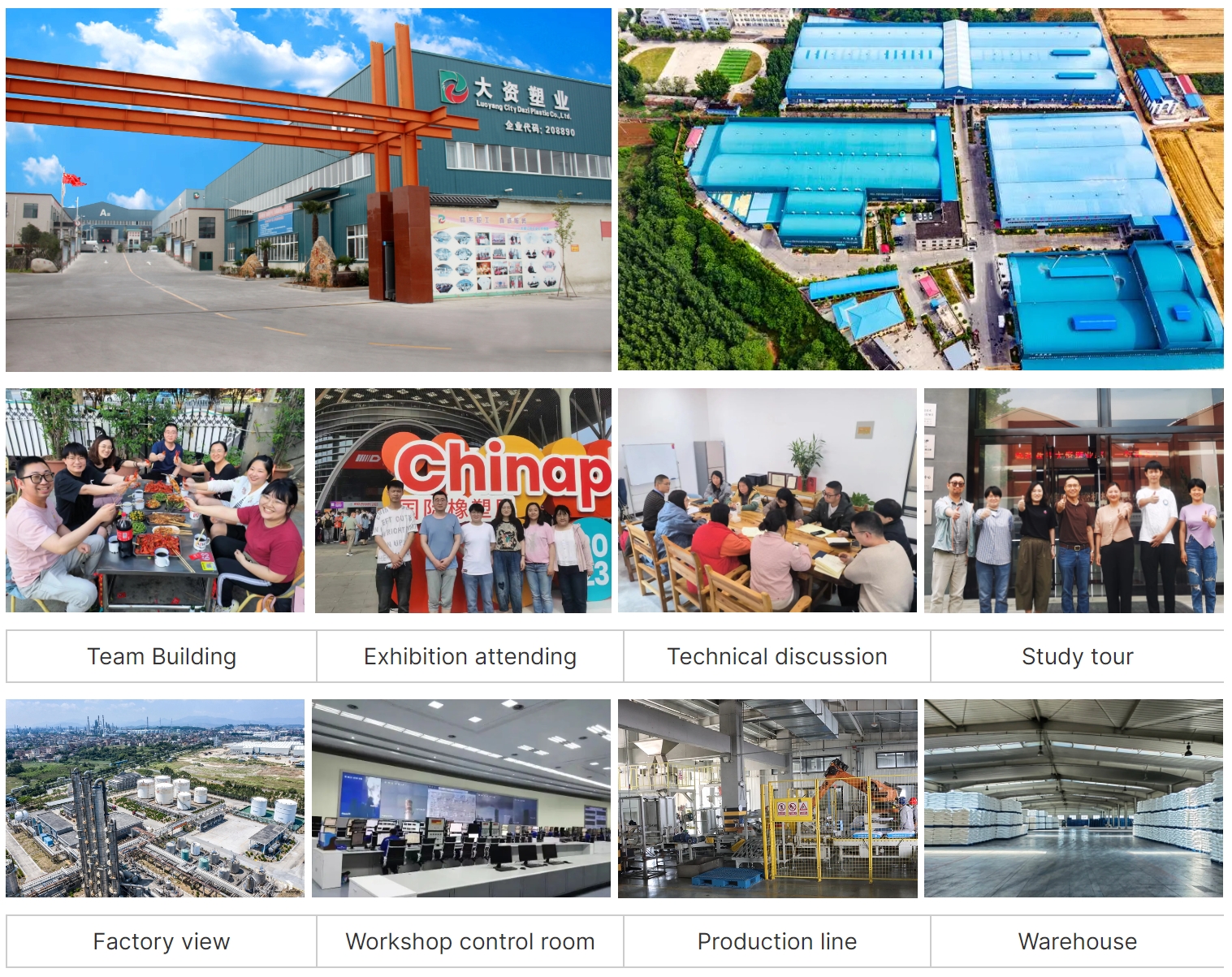

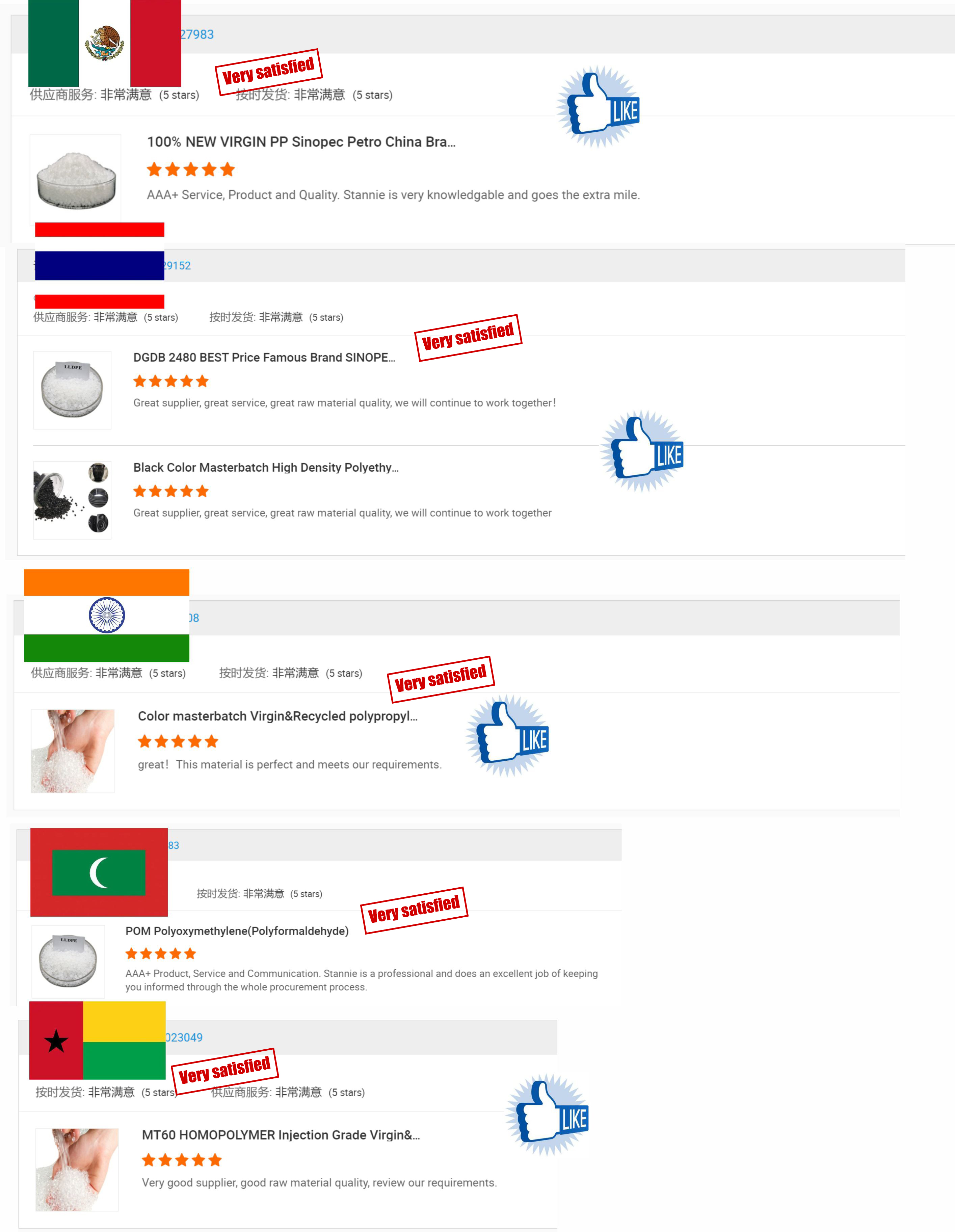

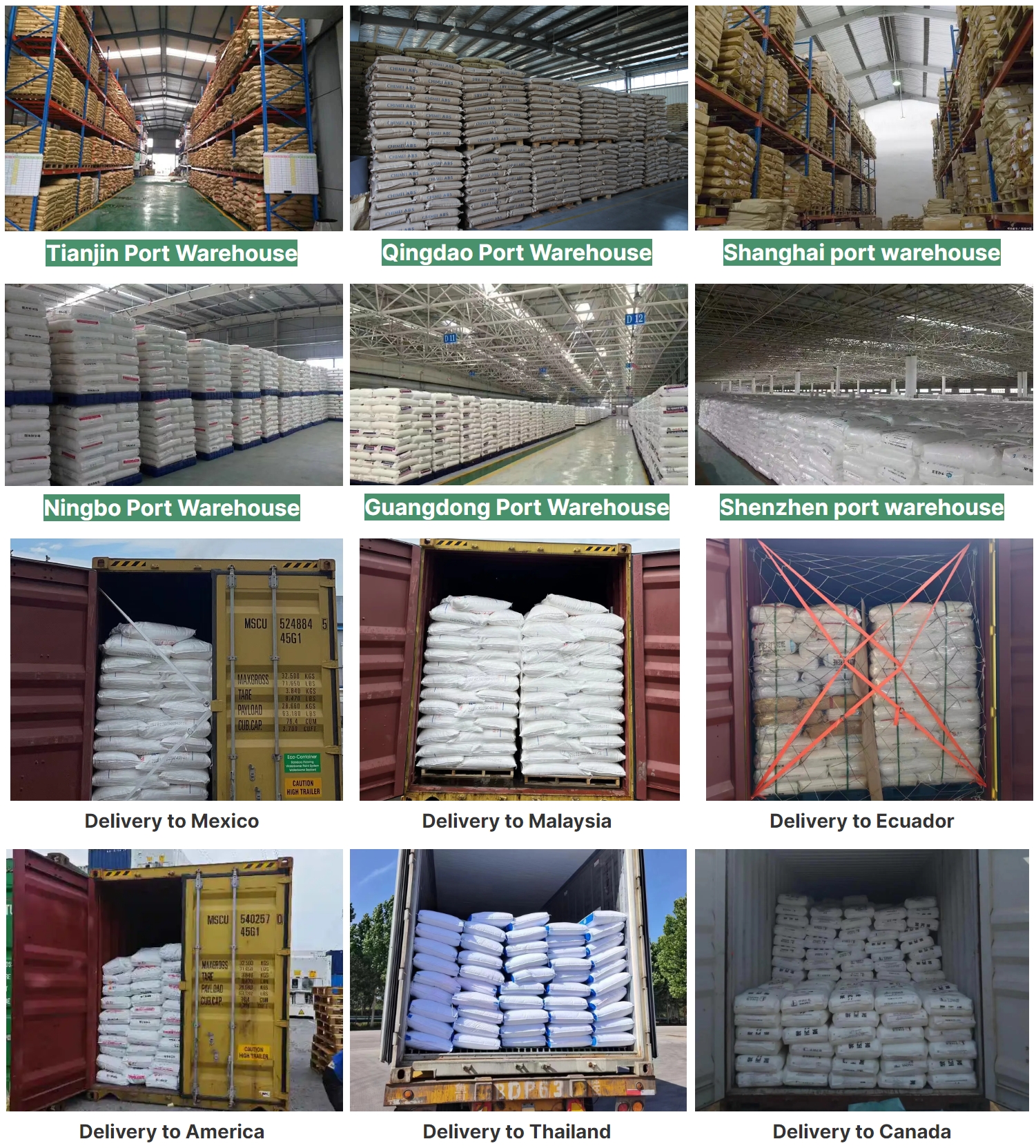

We have established long-term cooperative relations with more than 60+ well-known enterprises all over the world

Our company has 12 certifications and 57+ patents.

23 years' experience Professional purchasing consultant with a supply chain of 1200+ plastic raw materials in China.