ABS particles: The all-round player in the field of engineering plastics, empowering innovative manufacturing.

2025-04-24 15:05:24

In the industrial manufacturing and consumer goods sectors, the selection of materials often determines the performance and market competitiveness of products. ABS granules, as a high-performance engineering plastic, have become the "invisible champions" in numerous industries due to their unique comprehensive advantages. From household appliance shells to automotive parts, from toy building blocks to smart devices, their presence can be seen everywhere. Today, let's uncover the five core advantages of ABS granules and see how they empower modern manufacturing.

1. Strength and toughness in balance, outstanding durability

The molecular structure of ABS (Acrylonitrile-Butadiene-Styrene Copolymer) integrates the characteristics of three materials: acrylonitrile provides hardness and chemical resistance, butadiene gives toughness, and styrene ensures processing fluidity. This "golden ratio" makes the products formed from ABS granules highly impact-resistant, even in low-temperature environments, and less prone to cracking. For example, products such as children's toys and luggage cases that require frequent collisions, ABS's durability significantly extends their service life.

2. Easy to process and mold, with extremely high design flexibility

The melting fluidity of ABS granules is excellent, suitable for various processes such as injection molding, extrusion, and 3D printing, and can precisely replicate the details of complex molds. Designers can boldly implement curved surfaces, hollowing out, or thin-walled structures without worrying about material cracking. In addition, the surface of ABS products is smooth, allowing for direct electroplating or spraying, meeting the high aesthetic requirements of electronic products and automotive accessories.

3. Dual certifications for environmental protection and safety, no concerns for application

Modern ABS granules comply with international environmental protection standards such as ROHS and REACH, containing no heavy metals or harmful plasticizers, and are safe for use in sensitive fields such as food packaging and medical devices. Some modified ABS can also be recycled and reused, reducing environmental burdens, and aligning with the sustainable development trend.

4. King of cost performance, controllable cost

Compared to engineering plastics such as PC and nylon, ABS granules are more affordable in price, but their performance is close to that of high-end materials. By adding modification schemes such as flame retardants and UV inhibitors, they can replace metals or ceramics, significantly reducing production costs. For small and medium-sized enterprises, ABS is an ideal choice for balancing budget and quality.

5. Large space for modification, customizable functions

The "all-purpose" characteristic of ABS enables it to flexibly adapt to different scenarios:

Flame-retardant ABS: used for electrical components, certified by UL94;

Weather-resistant ABS: added with UV-resistant components, suitable for outdoor equipment;

Transparent ABS: replaces acrylic, combining transparency and toughness.

From daily necessities to high-tech equipment, ABS granules with balanced performance, flexible processes, and economic costs continuously drive manufacturing innovation. Whether enhancing product competitiveness or optimizing supply chain efficiency, choosing ABS means choosing reliability and unlimited possibilities.

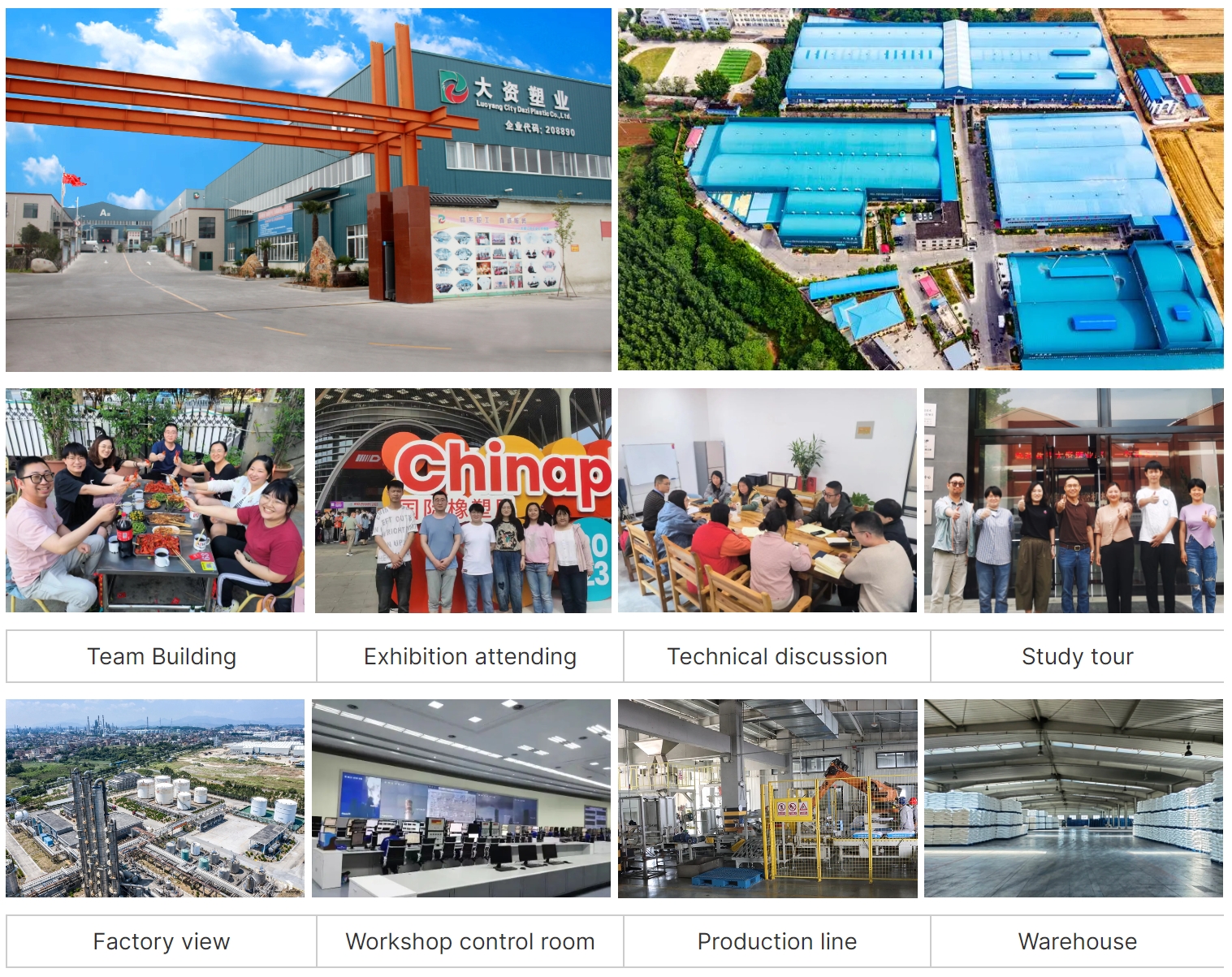

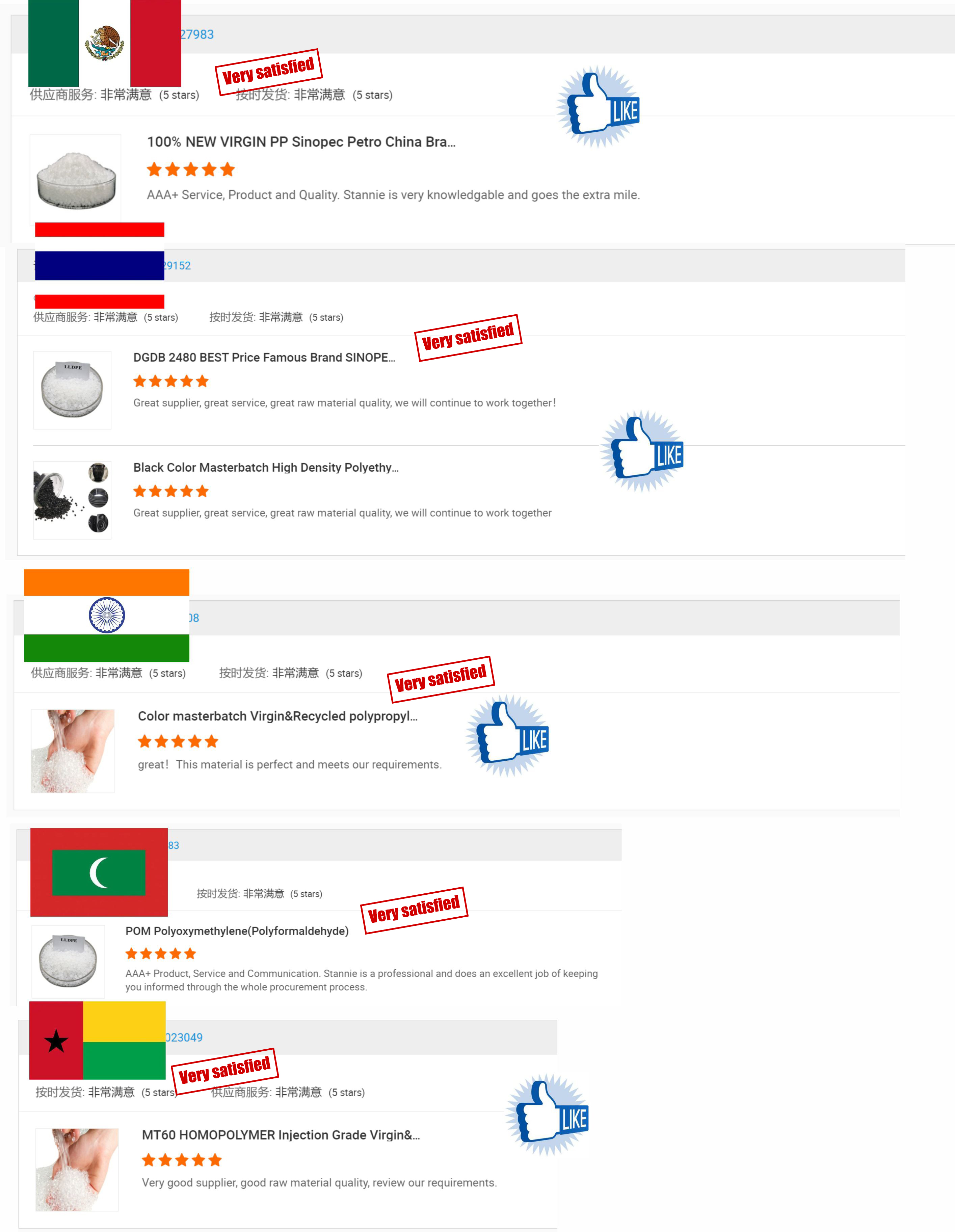

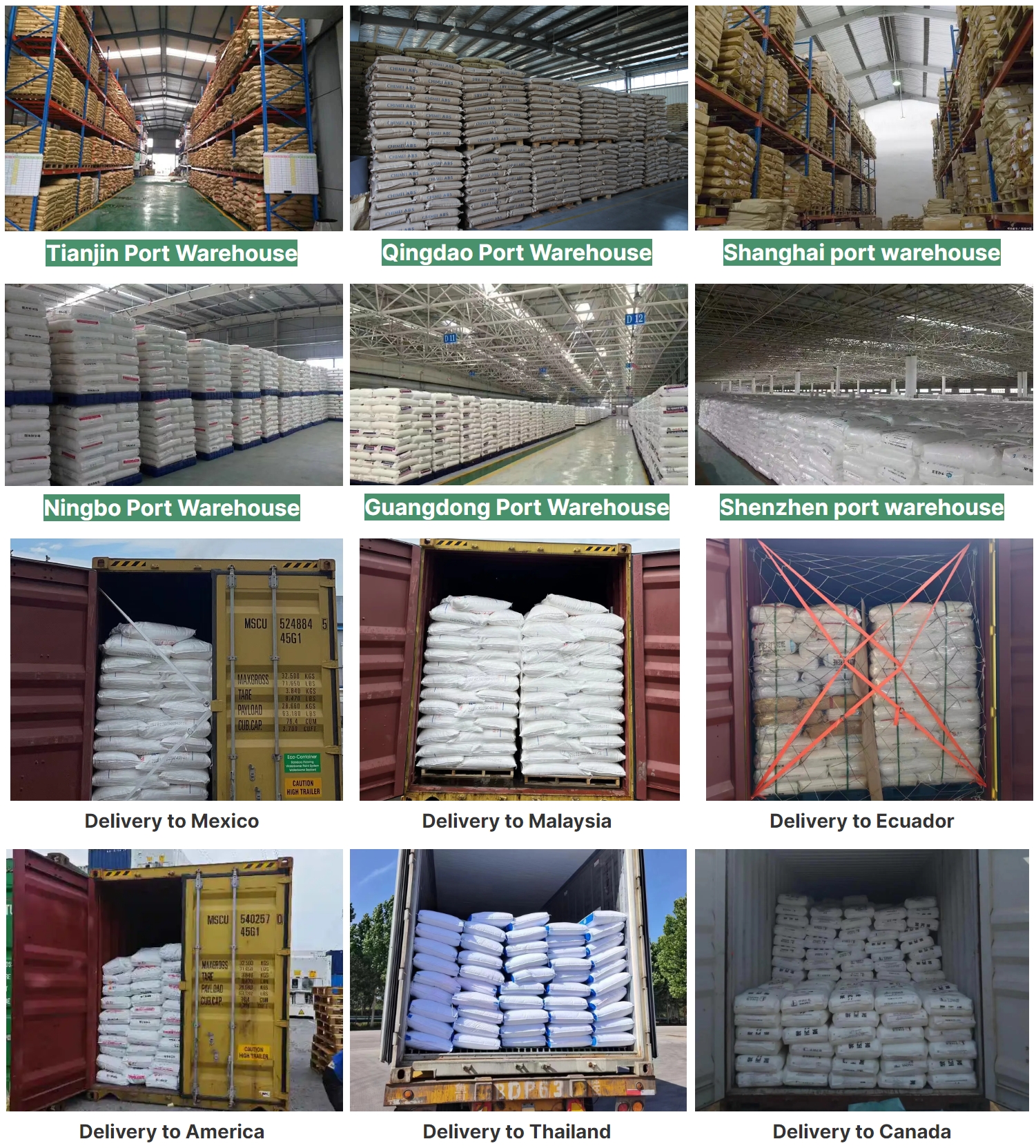

We have established long-term cooperative relations with more than 60+ well-known enterprises all over the world

Our company has 12 certifications and 57+ patents.

23 years' experience Professional purchasing consultant with a supply chain of 1200+ plastic raw materials in China.