Packing automotive fibre industrial polypropylene materials

Polypropylene (PP) is a linear hydrocarbon polymer, expressed as CnH2n. PP, like polyethylene (see HDPE, L/LLDPE) and polybutene (PB), is a polyolefin or saturated polymer. Polypropylene is one of those most versatile polymers available with applications, both as a plastic and as a fibre, in virtually all of the plastics end-use markets.

Category: Products > General plastics > Polypropylene

Email : sales@dazisuye.com

Tel : +86 15890096857

|

Specifications & Applications |

|||||

|

Grade: |

Other |

visual inspection |

Translucence |

||

|

Application: |

Washing machine parts, auto parts, home appliance housings |

||||

|

Notes: |

Processing conditions: Other |

||||

|

Technical parameters: |

|||||

|

Items: |

Test conditions (Statues) |

Test method |

Standard |

Units |

|

|

Physical performance |

Melting flow index |

2.16Kg |

Q/SY DS0513 |

28.3 |

g/10min |

|

Q/SY DS 0515 |

22.6 |

MPa |

|||

|

Q/SY DS 0515 |

18 |

GPa |

|||

|

Mechanical Properties |

Izod impact strength |

23℃ |

Q/SY DS 0517 |

19 |

J/m |

|

Izod impact strength |

-20℃ |

Q/SY DS 0517 |

287 |

J/m |

|

|

Big grains and small grains |

SH/T 1541 |

2.0 |

g/Kg |

||

|

yellow index |

Q/SY DS 0514 |

3.8 |

|||

|

ash content |

GB/T 93456 |

GB/T 9345 |

0.031 |

% |

|

Polypropylene brief introduction

Polypropylene (PP) is a linear hydrocarbon polymer, expressed as CnH2n. PP, like polyethylene (see HDPE, L/LLDPE) and polybutene (PB), is a polyolefin or saturated polymer. Polypropylene is one of those most versatile polymers available with applications, both as a plastic and as a fibre, in virtually all of the plastics end-use markets.

Development

Following the work by Ziegler in Germany, the process for producing "stereoregular" polymers was perfected by Professor Giulio Nattain in Italy. Natta produced the first polypropylene resin in Spain in 1954. Natta utilised catalysts developed for the polyethylene industry and applied the technology to propylene gas.

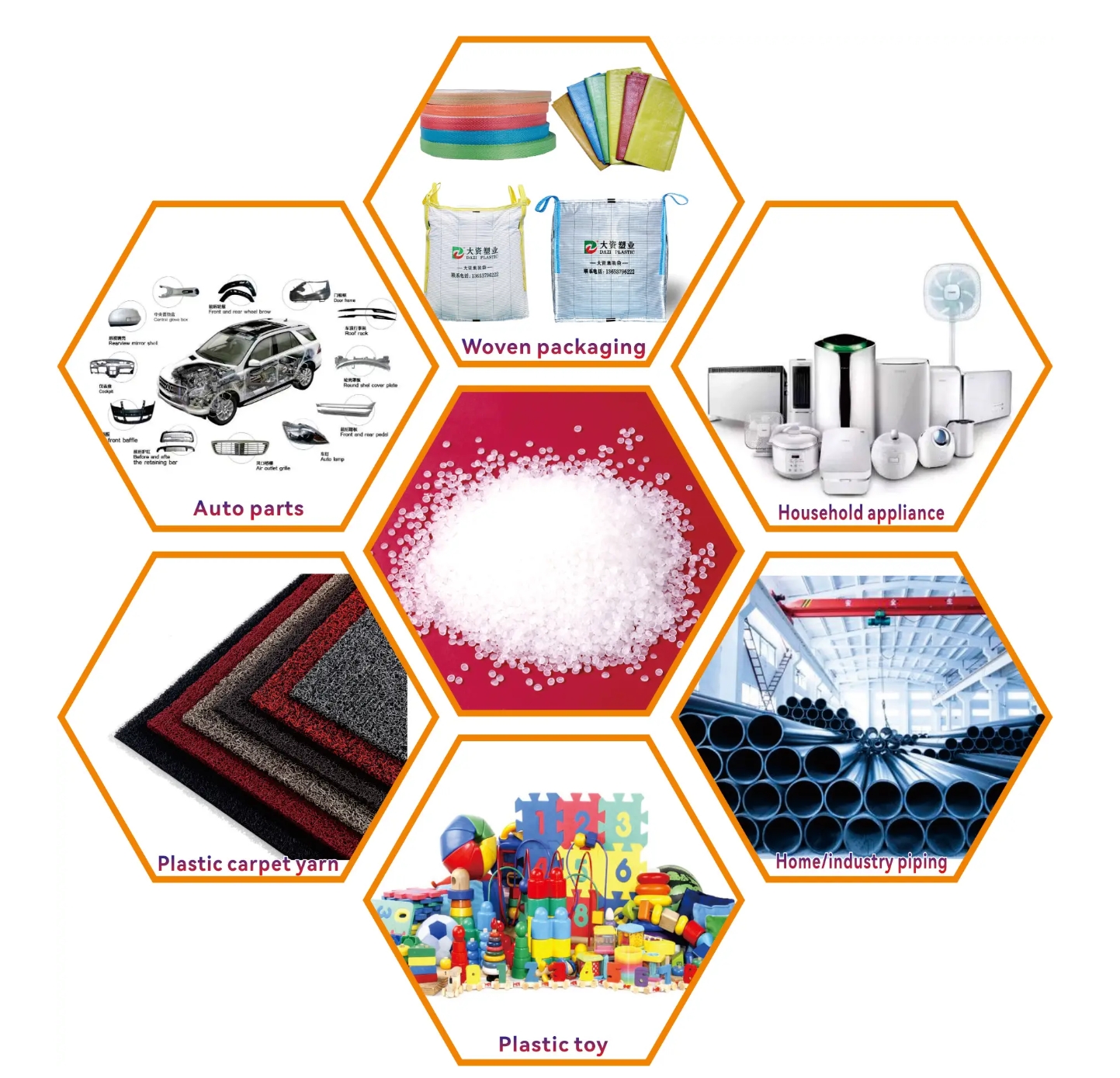

These new polymers with their ability to crystallise soon became popular and polypropylene is now a very successful product in many areas. Commercial production began in 1957 and polypropylene usage has displayed strong growth from this date. The versatility of the polymer (the ability to adapt to a wide range of fabrication methods and applications) has sustained growth rates enabling PP to challenge the market share of a host of alternative materials in plethora of applications including...

| Type | Product |

| mouldings | automotive components, sailing dinghies, etc. |

| fibres | carpets, bailing twine, clothing, etc. |

| tape | replaced jute |

| film | biaxially oriented film (OPP) |

| foam | structural foam, and low density packging (bead process similar to XPS) |

Oriented polypropylene (OPP) has seen considerable growth, having replaced cellophane in virtually all applications.

The properties of Polypropylene include...

Semi-rigid

Translucent

Good chemical resistance

Tough

Good fatigue resistance

Integral hinge property

Good heat resistance

PP does not present stress-cracking problems and offers excellent electrical and chemical resistance at higher temperatures. While the properties of PP are similar to those of Polyethylene, there are specific differences. These include a lower density, higher softening point (PP doesn't melt below 160oC, Polyethylene, a more common plastic, will anneal at around 100oC) and higher rigidity and hardness. Additives are applied to all commercially produced polypropylene resins to protect the polymer during processing and to enhance end-use performance.

| Homopol | Copolym | ||

| Density | kgm3 | 905 | 905 |

| Tensile Strength | Mpa | 33 | 25 |

| Tensile Modulus | Gpa | 1.4 | 1.0 |

| Elongation at Break | % | 150 | 300 |

| Hardness | Rockwell "R" Scale | 90 | 80 |

| Notched Izod Impact | kJm-1 | 0.07 | 0.1 |

| Heat Distortion Temp (HDT) | 0.45 MPa / °C | 105 | 100 |

| Heat Distortion Temp (HDT) | 1.80 MPa / °C | 65 | 60 |

| Volume Resistivity | logÙm | 19 | 19 |

| Oxygen Index | % | 17 | 17 |

3 Chemical Structure

Linear hydrocarbon polymer, little or no unsaturation. Similar to polyethylene in many properties, especially solution and electrical. However, the presence of the methyl group attached to every alternate backbone chain carbon atom can alter the properties in a number of ways:

(1) it can cause a slight stiffening of the chain - increasing the crystalline melting point (Tm);

(2) it can interfere with the molecular symmetry - depressing crystallinity and hence Tm.

Isotactic Polypropylene Molecular Image

Isotactic

Syndiotactic Polypropylene Molecular Image

Syndiotactic

Atactic Polypropylene Molecular Image

In the case of very regular polymers, ISOTACTIC form, the net result is a melting point some 30oC higher than that for HDPE.

The methyl group also has a chemical effect, i.e. tertiary carbon atom provides a site for oxidation - PP less stable than PE, also peroxides and radiation lead to chain scission rather than cross-linking.

Manufacturers quote "isotactic index" - amount insoluble in hot solvent - which indicates (?) the percentage isotactic polymer in the grade. N.B. usually 90-95% isotactic. Glass transition around 0oC presents problem of embrittlement and this can be altered by copolymerisation (with ethylene block copolymers) and/or blending with rubber, e.g EPM. Polypropylene does not crystallise so readily as polyethylene, it tends to supercool, and this becomes worse at higher molecular weights.

Applications

Buckets, bowls, crates, toys, medical components, washing machine drums, battery cases, bottle caps. Elastomer modified for bumpers, etc. Talc filled for additional stiffness at elevated temperatures - jug kettles, etc. OPP films for packaging (e.g. crisps, biscuits, etc.). Fibres for carpets, sports clothing.

Hot Tags: Packing automotive fibre industrial polypropylene materials , manufacturers, suppliers, factory, Customized

|

Category

|

Grade

|

MFI

|

Density

|

Major Applications

|

|

Homopolymer - Extrusion

|

F103

|

3.3

|

0.9

|

BOPP Film Grade - General Purpose, Lamination & Metallizable films

|

|

T30S

|

3.3

|

0.9

|

Raffia Tapes ,Woven Sacks for Packaging Fertilizers, Cement, Polymers, Carpet Backing ,FIBC etc.

|

|

|

T103

|

3.3

|

0.9

|

Thermoformed Cups, Containers & Other disposable items

|

|

|

F110

|

11

|

0.9

|

TQ and Cast Films for General Purpose Packaging etc.

|

|

|

Homopolymer – Injection Molding

|

M103

|

3

|

0.9

|

General Purpose Injection Molding

|

|

M106

|

6

|

0.9

|

General Purpose Injection Molding

|

|

|

M108

|

8

|

0.9

|

General Purpose Injection Molding

|

|

|

M110

|

10

|

0.9

|

General Purpose Injection Molding, Furniture etc.

|

|

|

Impact Copolymer – Injection Molding

|

M304

|

3.5

|

0.9

|

General Purpose Injection Molding

|

|

M310

|

10

|

0.9

|

Battery Boxes

|

|

|

M311T

|

10

|

0.9

|

Compounding, Automotive Components, Luggage and Industrial Components

|

|

|

M312

|

12

|

0.9

|

Compounding, Industrial Components, Automotive Components, Luggage, Pails, Houseware, Sanitary Wares etc.

|

|

|

M315

|

15

|

0.9

|

General Purpose Injection Molding

|

|

|

M325

|

25

|

0.9

|

Compounding, Automotive Components, Houseware, Appliances parts, Extrusion Coating

|

|

|

M340

|

40

|

0.9

|

Appliance & White Goods, Automotive component, Compounding,TWIM

|

|

|

M307

|

7

|

0.9

|

General Purpose Injection Molding

|

|

|

Random Copolymer – Blow Molding

|

B202S

|

1.9

|

0.9

|

Bottle & Containers for Medical and Transparent Products (e.g. IV Fluid Bottles) etc

|

|

B200

|

1.9

|

0.9

|

General Purpose Blow Molded & Thermoformed Items, Sheets for Files & Folders.

|

|

|

M212S

|

12

|

0.9

|

High Clarity Containers, Household items,Injection Syringe, Laboratory products & ISBM Bottles

|

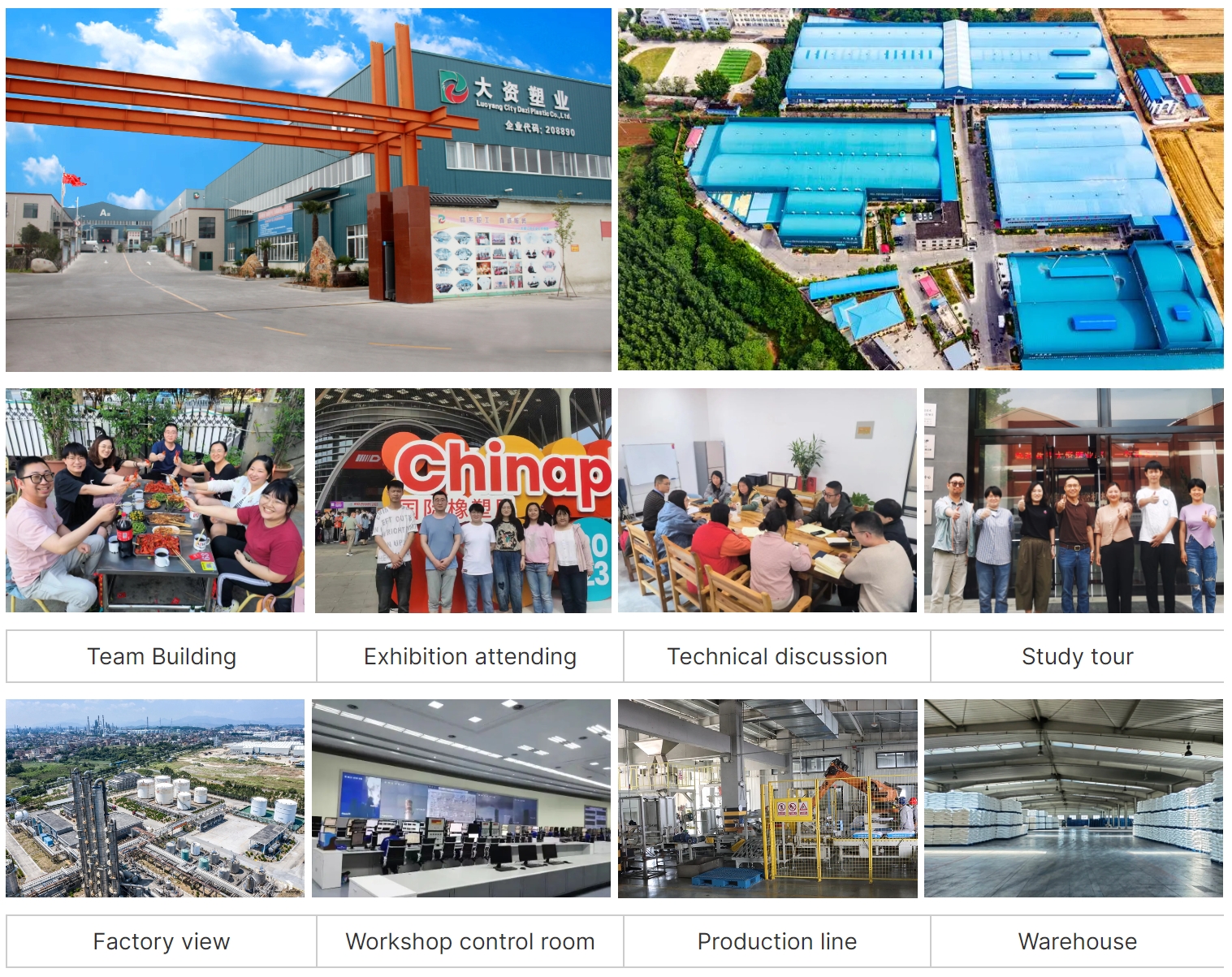

We have established long-term cooperative relations with more than 60+ well-known enterprises all over the world

Our company has 12 certifications and 57+ patents.

23 years' experience Professional purchasing consultant with a supply chain of 1200+ plastic raw materials in China.