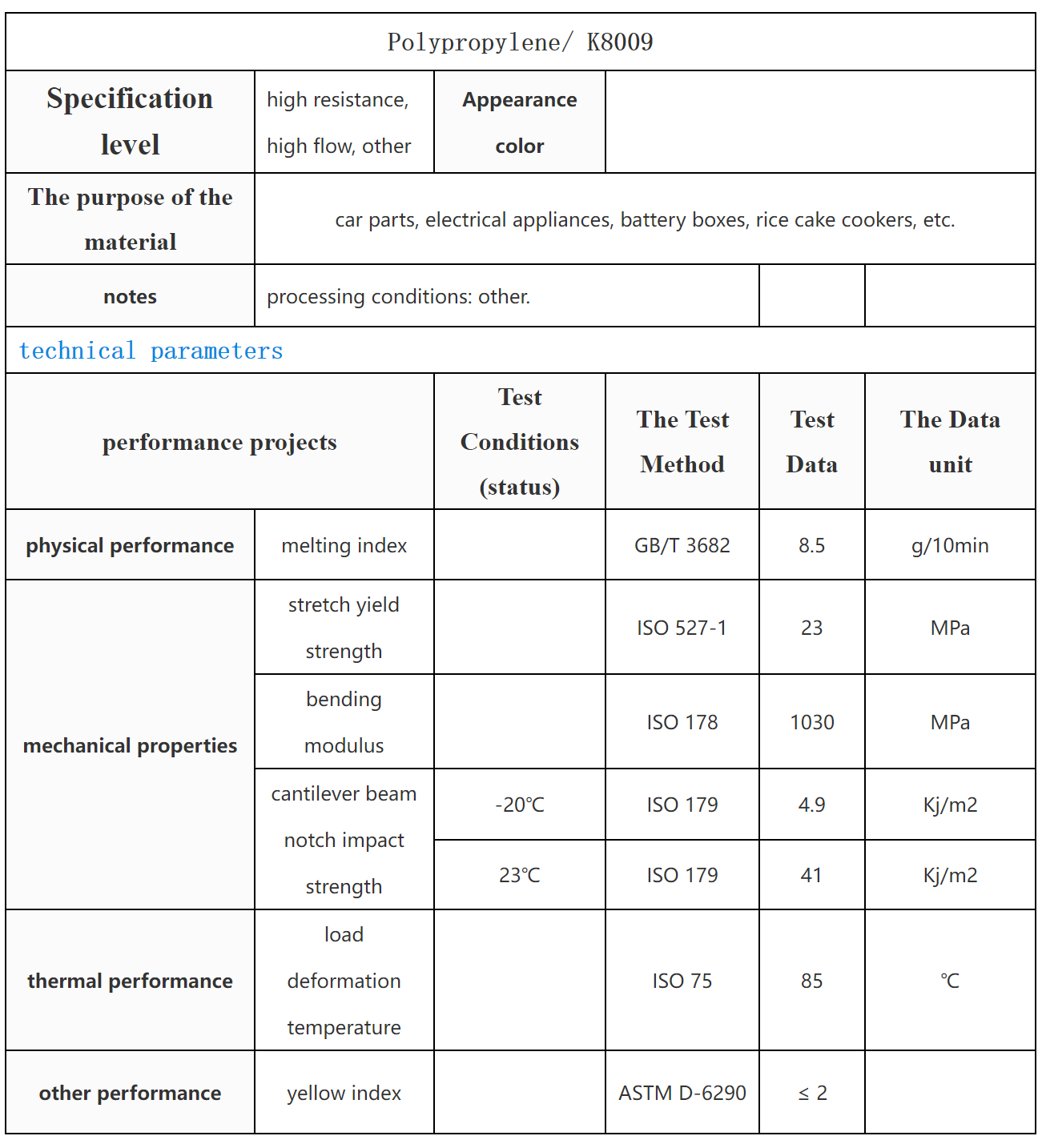

Polypropylene raw material K8009

Polypropylene is a polymer formed by the addition polymerization of propylene. It is white waxy material, transparent and light in appearance. The chemical formula is (C3H6) N, the density is 0.89 ~ 0.91g/cm3,

Category: Products > General plastics > Polypropylene

Email : sales@dazisuye.com

Tel : +86 15890096857

Introduction to Polypropylene

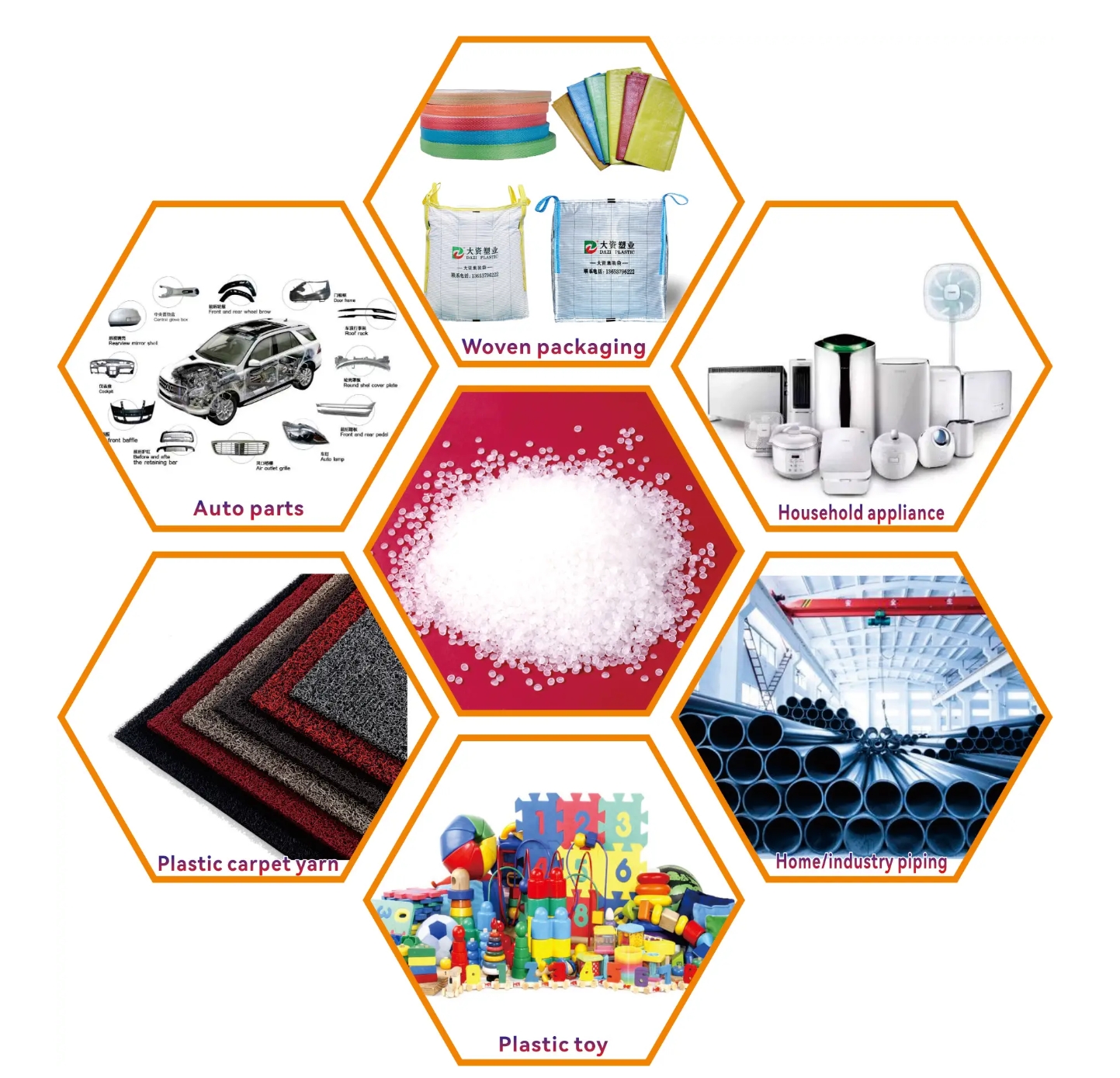

Polypropylene is a polymer formed by the addition polymerization of propylene. It is white waxy material, transparent and light in appearance. The chemical formula is (C3H6) N, the density is 0.89 ~ 0.91g/cm3, [1] inflammable, melting point is 189℃, softening at about 155℃, and the operating temperature range is -30 ~ 140℃ [2]. Under 80℃ can resist the corrosion of acid, alkali, salt solution and a variety of organic solvents, can be decomposed under high temperature and oxidation. Polypropylene is widely used in the production of fiber products such as clothing and blankets, medical instruments, automobiles, bicycles, spare parts, transportation pipes and chemical containers, as well as in the packaging of food and medicine.

Characteristics of PP plastic material

1, colorless, tasteless, non-toxic. 2, the appearance is white waxy, but transparent than PE. 3, low density: 0.9-0.91 grams/cubic meter, is one of the lightest plastics. 4, has a particularly high bending fatigue strength - 100 fold glue. 5, good heat resistance (120℃). 6. Good boiling water and steam resistance (high pressure disinfection products). 7. It is easy to age under the action of heat, oxygen and light.

PP plastic properties

1, physical properties: non-toxic, odorless, tasteless, milky white high crystalline density is only 0.9-0.91g/cm3, good stability to water. 2,thermal performance: has good heat resistance, its products can be disinfected and sterilized at the temperature above 100℃, in the condition of no external force, 150℃ is not deformed. Embrittlement temperature is -35℃, below -35℃ will occur embrittlement, cold resistance is not as good as polyethylene.

3, chemical stability: Chemical stability is good, besides can be concentrated sulfuric acid, nitric acid erosion, for other kinds of chemical reagents are stable, but the low molecular weight fatty hydrocarbon, aromatic hydrocarbon and chlorinated hydrocarbon can make polypropylene softening and swelling, such as its chemical stability at the same time there is some increase with the increase of the crystallinity, chemical pipe and fittings for the production, so the polypropylene anti-corrosion effect is good. 4, electrical properties: a high dielectric coefficient, and with the rise of temperature, can be used to make heated electrical insulation products. Its breakdown voltage is also very high, suitable for electrical accessories, etc. Voltage resistance, arc resistance is good, but the electrostatic degree is high, and copper contact is easy to aging.

|

Category

|

Grade

|

MFI

|

Density

|

Major Applications

|

|

Homopolymer - Extrusion

|

F103

|

3.3

|

0.9

|

BOPP Film Grade - General Purpose, Lamination & Metallizable films

|

|

T30S

|

3.3

|

0.9

|

Raffia Tapes ,Woven Sacks for Packaging Fertilizers, Cement, Polymers, Carpet Backing ,FIBC etc.

|

|

|

T103

|

3.3

|

0.9

|

Thermoformed Cups, Containers & Other disposable items

|

|

|

F110

|

11

|

0.9

|

TQ and Cast Films for General Purpose Packaging etc.

|

|

|

Homopolymer – Injection Molding

|

M103

|

3

|

0.9

|

General Purpose Injection Molding

|

|

M106

|

6

|

0.9

|

General Purpose Injection Molding

|

|

|

M108

|

8

|

0.9

|

General Purpose Injection Molding

|

|

|

M110

|

10

|

0.9

|

General Purpose Injection Molding, Furniture etc.

|

|

|

Impact Copolymer – Injection Molding

|

M304

|

3.5

|

0.9

|

General Purpose Injection Molding

|

|

M310

|

10

|

0.9

|

Battery Boxes

|

|

|

M311T

|

10

|

0.9

|

Compounding, Automotive Components, Luggage and Industrial Components

|

|

|

M312

|

12

|

0.9

|

Compounding, Industrial Components, Automotive Components, Luggage, Pails, Houseware, Sanitary Wares etc.

|

|

|

M315

|

15

|

0.9

|

General Purpose Injection Molding

|

|

|

M325

|

25

|

0.9

|

Compounding, Automotive Components, Houseware, Appliances parts, Extrusion Coating

|

|

|

M340

|

40

|

0.9

|

Appliance & White Goods, Automotive component, Compounding,TWIM

|

|

|

M307

|

7

|

0.9

|

General Purpose Injection Molding

|

|

|

Random Copolymer – Blow Molding

|

B202S

|

1.9

|

0.9

|

Bottle & Containers for Medical and Transparent Products (e.g. IV Fluid Bottles) etc

|

|

B200

|

1.9

|

0.9

|

General Purpose Blow Molded & Thermoformed Items, Sheets for Files & Folders.

|

|

|

M212S

|

12

|

0.9

|

High Clarity Containers, Household items,Injection Syringe, Laboratory products & ISBM Bottles

|

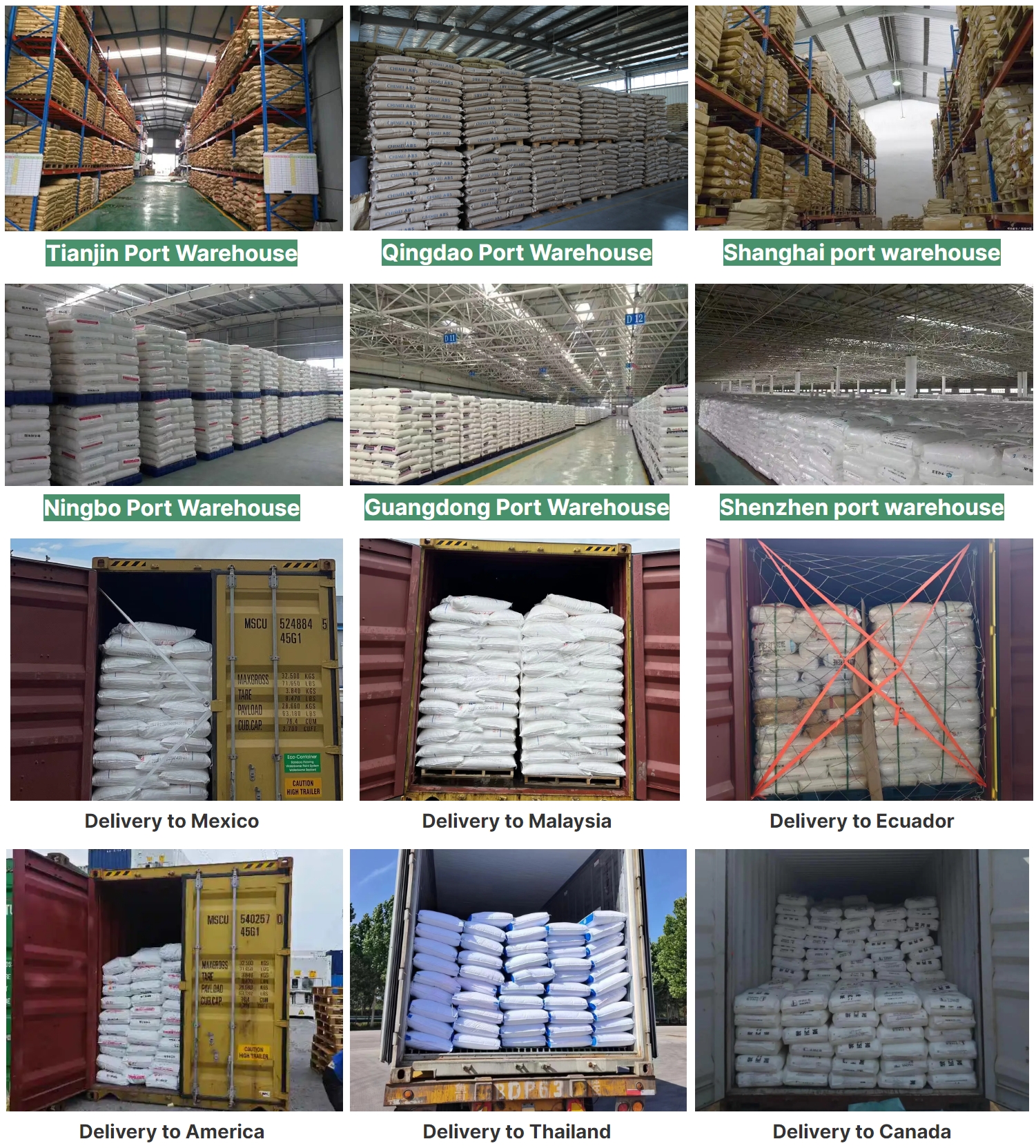

We have established long-term cooperative relations with more than 60+ well-known enterprises all over the world

Our company has 12 certifications and 57+ patents.

23 years' experience Professional purchasing consultant with a supply chain of 1200+ plastic raw materials in China.