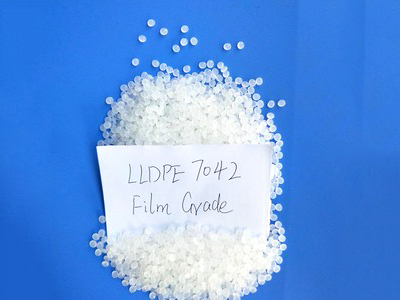

Lldpe 7042 grado de película

El polietileno 7042 es un material de polietileno con alta tenacidad y resistencia al desgaste. Es polimerizado a partir del monómero de etileno y tiene las características de baja densidad y alto peso molecular.

categorías: productos > Plástico para uso general > Polietileno

dirección : sales@dazisuye.com

Tel. : +86 15890096857

7042 polyethylene is a polyethylene material with high toughness and wear resistance. It is polymerized from ethylene monomer and has the characteristics of low density and high molecular weight. 7042 Polyethylene has a wide range of applications in industry and daily life, such as packaging materials, pipes, wire insulation materials and so on. This paper will introduce the parameters of 7042 polyethylene from the aspects of physical properties, chemical properties and application fields.

1, physical properties 7042 polyethylene has low density, high toughness and wear resistance. Its density is about 0.92 g/cm3 and its relative molecular mass is about 70.2 kg/mol. This polyethylene has high flexibility and elasticity, and can withstand large tensile forces and is not easy to break. In addition, 7042 polyethylene also has good wear resistance, able to maintain its integrity and performance under the conditions of friction and wear.

2, chemical properties 7042 polyethylene is a relatively stable polymer material, with good chemical resistance. It can withstand the erosion of a certain concentration of acids, bases and organic solvents, but it may be degraded or damaged under the action of some strong oxidants and strong acids and bases. In addition, 7042 polyethylene also has a certain resistance to ultraviolet light, and can resist ultraviolet light exposure to a certain extent.

3, application field 1, packaging materials: Because 7042 polyethylene has good softness and elasticity, it is often used to make plastic bags, plastic film and other packaging materials. The packaging material made of 7042 polyethylene has good tensile resistance and wear resistance, which can protect the packaging items from damage by external factors. 2, pipeline: 7042 polyethylene made of pipeline has good corrosion resistance and wear resistance, often used to transport liquid, gas or solid particles of the pipeline system. This piping material not only has a long service life, but also reduces energy consumption and maintenance costs. 3. Wire insulation material: 7042 polyethylene is often used as wire insulation material because of its good electrical insulation and heat resistance. It can effectively block the flow of current, but also can keep its performance stable in a certain temperature range. 4. Other applications: 7042 polyethylene is also often used to make plastic containers, plastic furniture and other daily items. Due to its good wear resistance and toughness, products made of 7042 polyethylene have a long service life and a better use experience.