Inyección de autopartes moldeando materiales de polipropileno de grado

Código HS :3902100090

Color: transparente/translúcido/opaco

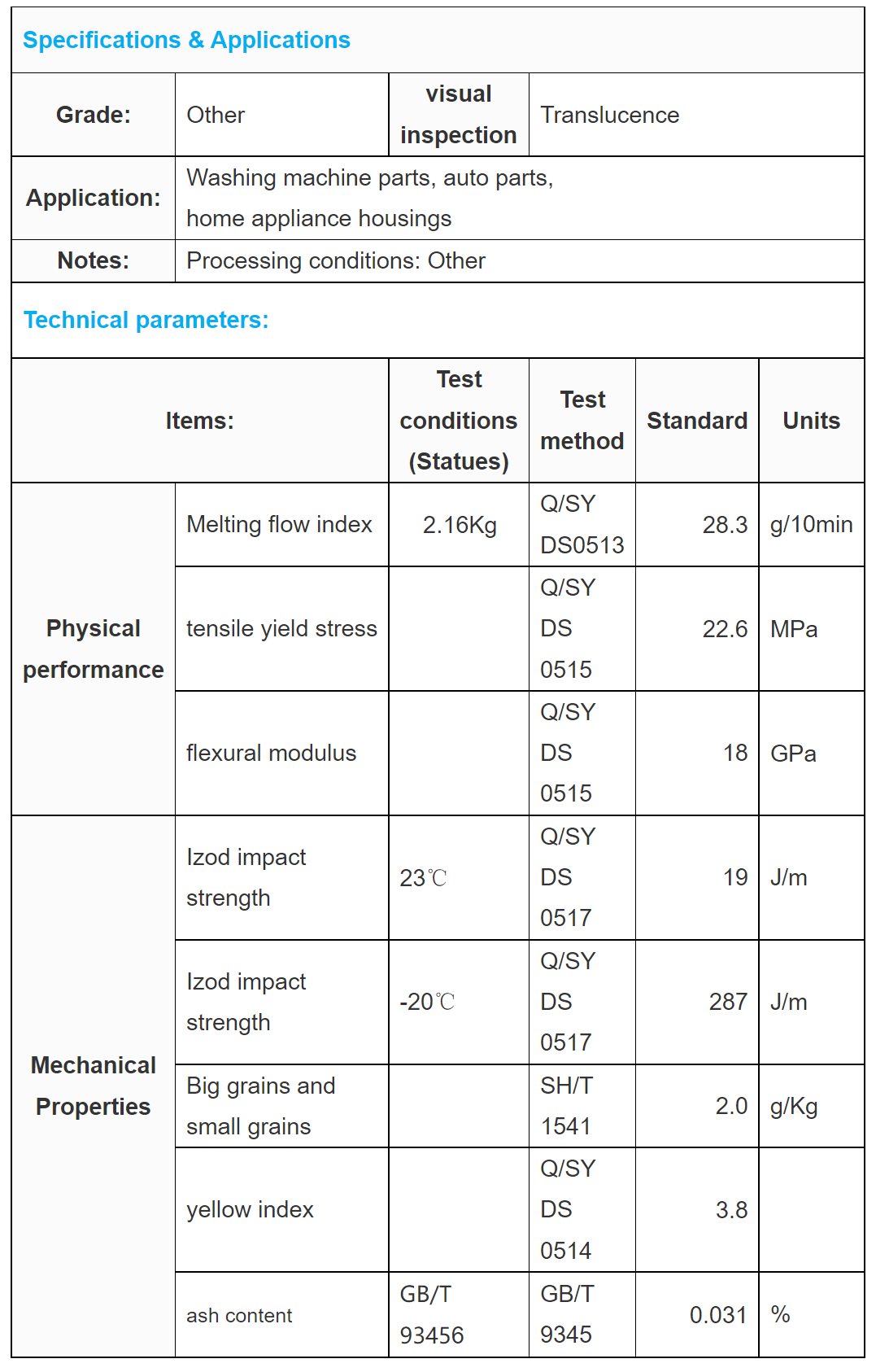

Caudal de masa fundida o índice de flujo de masa fundida :28

CAS:9002-88-4

Embalaje :25KG/ bolsa

categorías: productos > Plástico para uso general > Polipropileno

dirección : sales@dazisuye.com

Tel. : +86 15890096857

The Advantages of Natural Polypropylene for Automotive Manufacturing

The following qualities of natural polypropylene also make it excellent to use in automotive manufacturing.

PP’s a Bad Conductor

Polypropylene is classified as an insulator, making it suitable for manufacturing electronic components such as capacitors and audio equipment. Studies show that one in five drivers, plan to purchase a purely electric car within the next five years. As such, the automotive industry is looking to embrace broader electrical applications – and PP could well be the answer.

PP Boasts a High Melting Point and is Highly Malleable

The plastic has a high melting point (130 degrees celsius) and, when melted, is highly malleable. This makes polypropylene safer to use around heat than some other materials. Additionally, it melts into a liquid that can then be molded into any desired shape. Therefore, reheating after cooling without significant degradation, making this material incredibly versatile.

High Tensile Strength

Polypropylene can withstand up to 4800 psi, making it suitable for applications involving heavy loads or rugged use.

You Can Transform Polypropylene Into Fiber Form

Therefore, allowing the creation of mesh-like surfaces that can be used in car interiors.

Polypropylene is a Low-Density Material

As such, it significantly reduces costs and fuel consumption associated with more substantial vehicles. Manufacturers can, therefore, use PP to decrease a car’s weight, making them more environmentally and economically appealing.

The Future of Automotive Manufacturing Lies in High-Quality Plastics

With the plastic market on the rise, it’s no surprise versatile materials like natural polypropylene are on the up. The future sees an increased demand for more lightweight, environmentally friendly cars, so manufacturers should look towards using PP to reduce the weight of their vehicles.